Comebak Return Conveyor

Specifications

- Pneumatically clutched infeed roller

- Urethane hold down pinch wheel

- Urethane transfer belts

- Return side powered rollcase with PVC sleeved 1.9″ rollers

- Raised bed HDPE belt slides

- Steel shielded deck

- PTO shaft driven swing out powered return conveyor

- Heavy duty laser cut square tubing frame

- 110V/1Ph Motor & Controls

- 2HP on Larger Units

- Nylon chain deck transfer

- Infeed rollcase lift tray for heavier applications

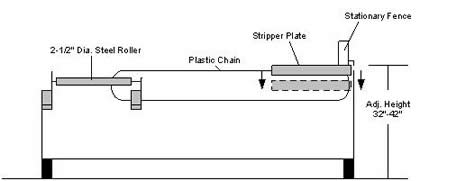

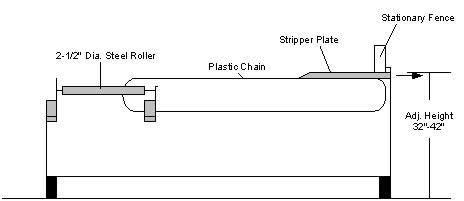

- Clutched stripper chain transfers in lieu of retractable shelf for high speed application

- Machine decks and returns can be quoted in any width and length

- Can be paired and interlaced with accumulating transfer or pack off decks

- Extended length infeed arms with floor supports for large pan- els

- Pass Thru option for processing products straight through

- A feed roller guides parts onto the receiver.

- (SP) Stripper Plate is retracted under fence, or (TR) Receiver roller bed is lowered under chain transfer level.

- The process is continuous, so parts may be butt-fed!

- MaxDrive System for a lifetime of low maintenance operation (NO RUBBERBANDS TO WELD!)

- Urethane Infeed Roller ensures total part acceptance

- Torque-Sensing Clutch exactly matches the speed of your processing machine

- Urethane transfer belting for low impact, long life lateral part transfers

- Variable Speed for instantaneous speed adjustment at the operator’s fingertips

- Variable-Speed Rollers so the roller speed can match speed of processing machine

- Swing-Out Return gives easy access to your processing machine for maintenance or adjustments

- Continuous Process allows butt-fed parts

Mobile Return / Hinged Swing-Out or Pinned Roll-Away

Features

LCD Display

Auto feeding

Cross Dado Machine

Gang Drill Machine

Video

Gallery

Comeback Indeed